This laser cleaning machine is a new generation of high-tech products for surface cleaning. It has advantages of easy control, easy automation integration, no chemical reagents, surface cleaning, High cleanliness, high precision, environmentally friendly, safe and reliable, almost no damage to the base, able to solve many problems that cannot be solved by traditional cleaning. Not only can it be used to clean organic pollutants, it can also clean in organic substances including metal rust, metal particles, dust, etc. The application effects include: rust removal, paint stripping, oil removal, cultural relic restoration, glue removal, coat removal.

Product Features

Laser Cleaning Solution

- No grinding, non-contact cleaning, Avoids secondary pollution.

- High cleaning precision, strong controllability, no consumables, and strong environmental protection

- Easy to control, just power on, can be hand-held or use with manipulator to implement automatic cleaning.

- High cleaning efficiency, save time.

- The system is stable, long lifespan, one-time investment, economical and efficient.

Laser Cleaning Process

The beam energy emitted by the laser is absorbed by the contamination layer on the surface to be treated, and the shock wave causes the contamination to evaporate or peel off instantaneously; with the correct laser parameters and optimal wavelength, the base material will not be damaged or melted.

Effect Contrast

Sample Pictures

Degreasing Metal Parts

Tire Mould Degumming

Flange surface removal coating

Auto Parts Rust Removal

Mechanical Surface Oxide Removal

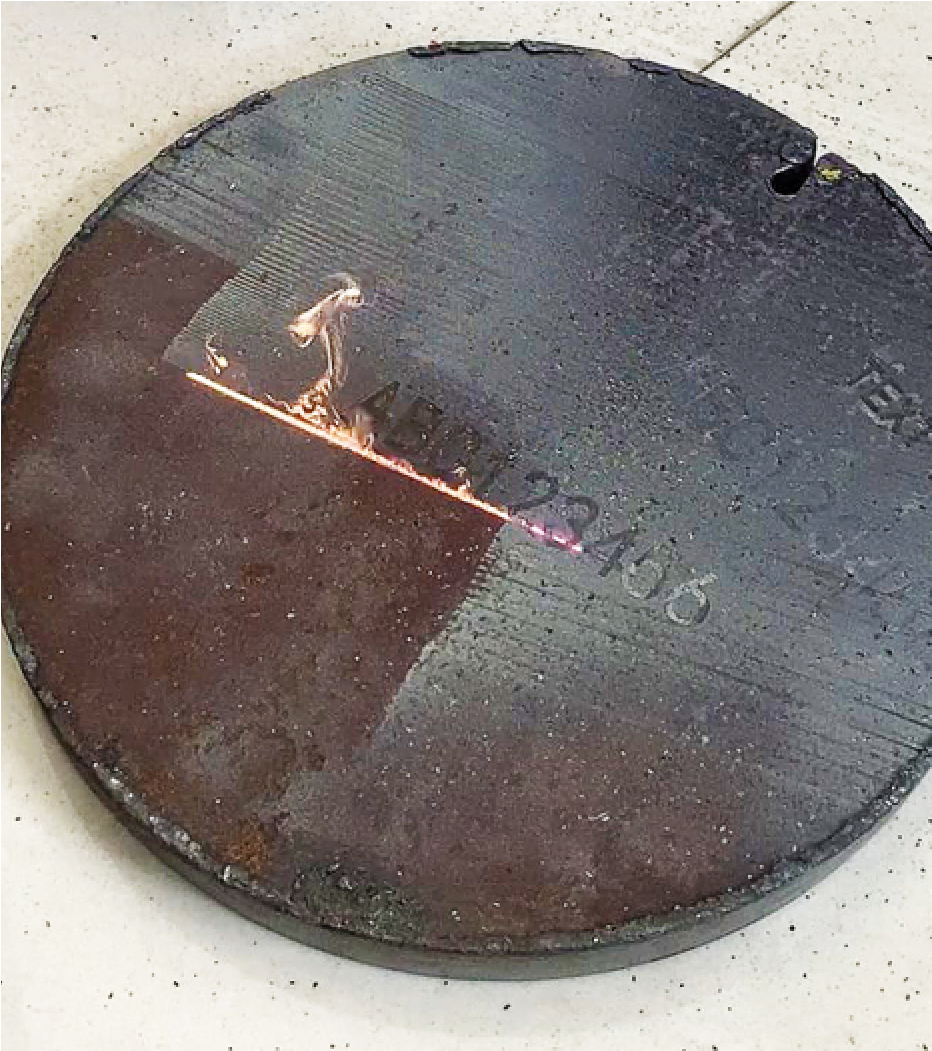

Mechanical Base Plate Rust Removal