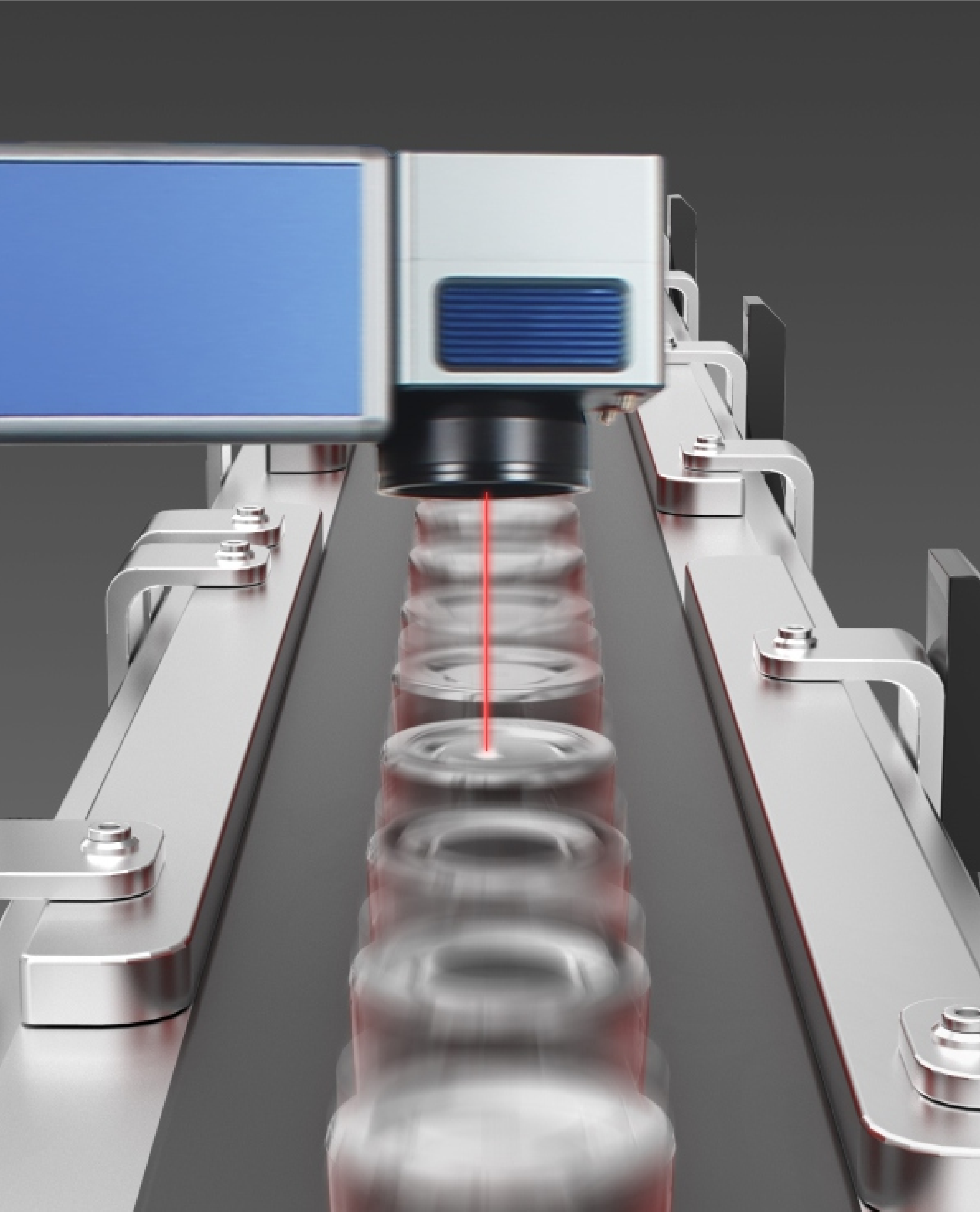

The T series fiber flying laser printer is a high-speed continuous marking machine designed to improve productivity. It adopts industrial-grade high-performance laser source which are with stable performance, fast processing efficiency and marking speed on the production line. It can reach high speed up to 200 meters per minute (single-line 2MM-high numbers and letters) with high-yield application identification requirements, it mainly used in production date, anti-counterfeiting, medical and food packaging industries. This model supports functions such as automatic encoding, serial number, batch number, date, barcode, two-dimensional code, automatic number skipping, etc., to meet the needs of customers in different industries.

Fiber laser online marking machine is suitable for online marking of most metal materials and some non-metallic materials with surface treatment, such as metal products, PVC, HDPE, aluminium film, rubber and plastics. It is widely used in the production of personal care products, food and beverage packaging, wine, dairy products, electronic components, chemical building materials and other fields, and the expiration date, batch number, shift, manufacturer name and logo and other graphics and text markings.

Laser source: CO2/Fiber/UV laser

Weight: 58KG

Dimension: 510x660x1460mm

Marking range: 70/110/150mm

User Interface: USB/built-in Touch scren

Product Size

FRONT OF THE DEVICE

RIGHT SIDE OF EQUIPMENT

BACK OF THE DEVICE

LEFT SIDE OF DEVICE

Scope of Application

Electronic components and electronic devices

Electrical components

Aviation and automobiles

Food and beverages and fast moving goods

Medicines and medical devices

Cosmetics, personal and home care products

Laser Marking Advantages

With the development of the national economy driving the progress of various industries, the laser marking equipment plays a pivotal role in the production line. Laser marking equipment shows the unique personality of the product through packaging, which is a key part of the enterprise to win the trust of consumers.

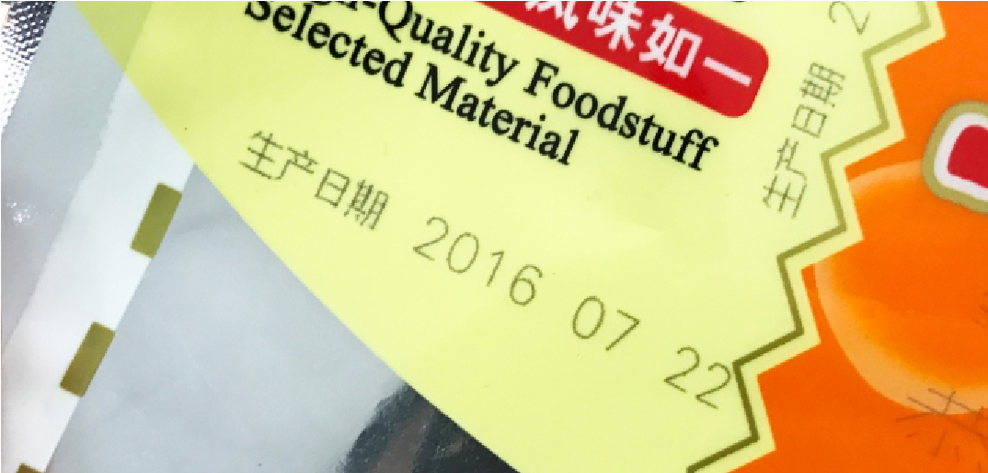

The three phase (production date, expiration date and batch number) and traceability code are assigned to each through the identification equipment, which is required by various industries, especially the fast-moving consumer goods industry. The current main processing methods are ink coding and laser coding.

Compare the Pros and Cons

Product Characteristics

MARKING SPEED UP TO 200 METERS PER MINUTE

This is the industry's fastest marking laser coding system, with a marking speed of up to 200 m/min (single line of 2MM-high numbers and letters), which can be used in medium-speed or high-speed production lines

RELIABLE AND DURABLE FIBER LASER SOURCE

It adopts a high-quality fiber laser light source, which is in uniform laser power density and highly focused laser beam Achieved a better logo contrast and the working life of the laser can reach 100,000 hours

COMPACT DESIGN AND FLEXIBLE CONFIGURATION

This model uses compact laser printer marking head to achieve simple integration to reduce installation costs and improve positioning flexibility

FLEXIBLE INSTALLATION WAY, CONVENIENT INSTALLATION POSITION ADJUSTMENT

The flying model is specially designed for high-speed production lines, which can be flexibly combined with production lines for installation and use. The frame can be moved up and down and left and right to adjust, the marking head can also be rotated 360° for marking.

Sample Pictures

Marking of soda cans

Marking of hardware parts

Electronic components

Marking of iron wire

ABS hose marking

Plastic bag date production marking